Notice: this Wiki will be going read only early in 2024 and edits will no longer be possible. Please see: https://gitlab.eclipse.org/eclipsefdn/helpdesk/-/wikis/Wiki-shutdown-plan for the plan.

Difference between revisions of "BaSyx / Reference Projects"

m (Fixes BaSyPaaS overview) |

m |

||

| (11 intermediate revisions by 3 users not shown) | |||

| Line 4: | Line 4: | ||

'''Retrofitting of Legacy Machines''' | '''Retrofitting of Legacy Machines''' | ||

| − | ''"BaSys | + | ''"BaSys structures our process data" |

- Marcel Kettering, Business Manager, WICO Textilbeschichtung und -kaschierung GmbH'' | - Marcel Kettering, Business Manager, WICO Textilbeschichtung und -kaschierung GmbH'' | ||

| − | During production, | + | During production, machines in the shopfloor generate valuable process information which helps manufacturers in decision-making. A big challenge is to make this data accessible in one place, especially if data is connected from legacy machines without Industrie 4.0 interfaces. The Arendar IoT-Gateway collects "live" process information from shopfloor assets and makes it available for further processing. The Arendar connects shopfloor devices through analogue, digital and network I/O with the Eclipse BaSyx middleware and enables access to device data. Asset Administration Shells (AAS) and AAS sub models present data from different sources in a unified and structured manner and enable data access through defined APIs. The result is a digital production process that stores data from all relevant sources in a digital process model, which can be used in various ways. It provides holistic live process images to decision-makers who use them to identify and resolve problems faster. With the continuous process monitoring, manufacturers can detect machine failures earlier, control product quality during the production and perform real-time decision-making. Consequently, this improves the market responsiveness, reduces the maintenance costs and increases the production efficiency. |

|- | |- | ||

| | | | ||

| Line 19: | Line 19: | ||

|[[File:Arend.png|left|120px|Arend |link=https://www.arend-automation.com/home-eng]] | |[[File:Arend.png|left|120px|Arend |link=https://www.arend-automation.com/home-eng]] | ||

| | | | ||

| − | |[[File: | + | |[[File:DFKI-Logo.png|left|120px|DFKI |link=https://www.dfki.de/en/web/about-us/locations-contact/kaiserslautern/]] |

| | | | ||

|[[File:BaSys.PLM.logo_iese.png|left|120px|Fraunhofer IESE|link=https://www.iese.fraunhofer.de/en.html]] | |[[File:BaSys.PLM.logo_iese.png|left|120px|Fraunhofer IESE|link=https://www.iese.fraunhofer.de/en.html]] | ||

| Line 49: | Line 49: | ||

|[[File:BaSys.PLM.basysplm_en.png|left|300px|Overview of BaSys<sup>PLM</sup>]] | |[[File:BaSys.PLM.basysplm_en.png|left|300px|Overview of BaSys<sup>PLM</sup>]] | ||

| | | | ||

| − | '''Integration of | + | '''Integration of PLM Systems (BaSys<sup>PLM</sup>)''' |

''"Eclipse BaSyx with its interoperable architecture enables us and our customers to bring product data directly from product development to manufacturing. This is relevant for highly variable Configure-to-Order products (-> lot size 1). Also feedback from the shop floor to the engineering (product type) as well as to single products (instances -> Digital Twins) can be realized."'' | ''"Eclipse BaSyx with its interoperable architecture enables us and our customers to bring product data directly from product development to manufacturing. This is relevant for highly variable Configure-to-Order products (-> lot size 1). Also feedback from the shop floor to the engineering (product type) as well as to single products (instances -> Digital Twins) can be realized."'' | ||

| − | - Christian Muggeo, Team Lead | + | - Christian Muggeo, Team Lead Engineering Transformation, CONTACT Software GmbH |

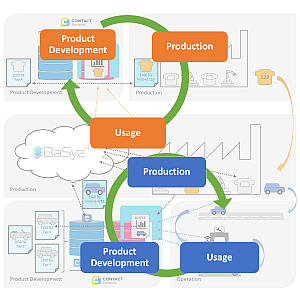

| − | In the area of product development, PLM systems are the central data hub. They consider the entire product lifecycle from planning to disposal and provide holistic management of all data and information that is processed and distributed during the development or modification of products. | + | In the area of product development, PLM systems are the central data hub. They consider the entire product lifecycle from planning to disposal and provide holistic management of all data and information that is processed and distributed during the development or modification of products. The BaSys-PLM-coupling connector enables PLM data from product development to be reused in subsequent production. This connector enables BaSyx to control and adapt production processes based on PLM data. Conversely, production data can be transferred from Eclipse BaSyx to a PLM system. The BaSyx PLM coupling therefore enables production data to be linked with data from the entire product lifecycle and to use this data for continuous product improvement. For many applications, the detour via an ERP/MES system can also be omitted, i.e. machines can communicate directly with the PLM system. |

| − | The BaSys-PLM-coupling | + | |

| − | + | ||

|- | |- | ||

| | | | ||

| Line 97: | Line 95: | ||

'''Information exchange with digital twins''' | '''Information exchange with digital twins''' | ||

| − | + | Many production processes are embedded into supply chains. Product related information is relevant throughout the whole product lifecycle and therefore needs to be exchanged between companies. Pickert & Partner GmbH and HPO Häfner Präzisionsteile Oberrot GmbH use Eclipse BaSyx to collect and provide product quality and calibration data that is exchanged with customers. This connection of product data and the IT that is enabled with Asset Administration Shells of Eclipse BaSyx realizes a horizontal integration that supports efficient data exchange and also enables new data-driven business models. | |

| + | |||

|- | |- | ||

| | | | ||

| Line 140: | Line 139: | ||

'''Digitalization of manufacturing process''' | '''Digitalization of manufacturing process''' | ||

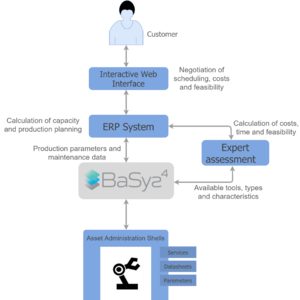

| − | + | Digitalization of production processes yields considerable advantages for small scale enterprises (SMEs) in terms of optimized product and production planning. Eclipse BaSyx enables digital production processes that support the evaluation of orders with data from previous shipments. Eclipse BaSyx realizes Asset Administration Shells and Sub Models that provide process data to the ERP system, which implements the business logic for deciding about accepting or rejecting an order. This empowers SMEs to quickly, efficiently and reliably evaluate and plan the production as well as promptly meeting short term customer inquiries. Since the checking and creation of order processes can be automated, substantial improvement in flexibility and cost efficiency in the process of order acceptance in comparison to the legacy, and manual paper-based processes is realized. | |

|- | |- | ||

| Line 150: | Line 149: | ||

|[[File:BaSys.Ellenberger_logo.jpg|left|120px|Ellenberger |link=https://www.ellenberger.org/]] | |[[File:BaSys.Ellenberger_logo.jpg|left|120px|Ellenberger |link=https://www.ellenberger.org/]] | ||

| | | | ||

| − | |[[File: | + | |[[File:DFKI-Logo.png|left|120px|DFKI |link=https://www.dfki.de/en/web/about-us/locations-contact/kaiserslautern/]] |

| | | | ||

|[[File:BaSys.PLM.logo_iese.png|left|120px|Fraunhofer IESE|link=https://www.iese.fraunhofer.de/en.html]] | |[[File:BaSys.PLM.logo_iese.png|left|120px|Fraunhofer IESE|link=https://www.iese.fraunhofer.de/en.html]] | ||

| + | |} | ||

|} | |} | ||

| + | {| | ||

| + | | | ||

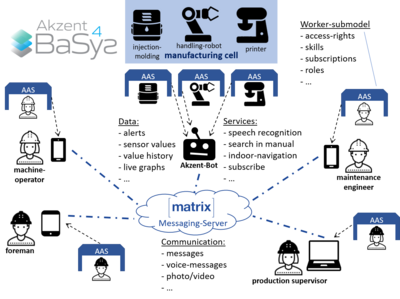

| + | '''Next generation shopfloor communication''' | ||

| + | The integration of Eclipse BaSyx with messenger services enable a new communication style between workers and the shopfloor. This integration enables employees to flexibly access and exchange information by using BaSyx together with the Matrix Messenger. Chat bots give access to live machine data and services. They access production assets through Asset Administration Shells (AAS) to provide e.g. live data analysis or machine manuals on request. Also, threshold-breach alerts can be configured for relevant sensor values. Other possible applications are speech recognition as additional human machine interface, and indoor navigation. By using a hosted messenger, messages are routed thorugh a dedicated Matrix Messaging Server, instead of using public messenger services. | ||

| − | + | |[[File:Akzent-Overview.png|left|400px|Overview of Akzent4BaSys]] | |

| + | |- | ||

| + | | | ||

| + | | | ||

| + | {| | ||

| + | |[[File:GS-Logo.png|left|120px|GS Kunsstofftechnik|link=https://en.gs-kunststofftechnik.de/]] | ||

| + | | | ||

| + | |[[File:VESATEC-Logo.png|left|120px|VESATEC|link=https://www.vesatec.de/]] | ||

| + | | | ||

| + | |[[File:Kybeidos-logo.png|left|120px|Kybeidos|link=https://www.kybeidos.de/en/home]] | ||

| + | | | ||

| + | |[[File:DFKI-Logo.png|left|120px|DFKI |link=https://www.dfki.de/en/web/about-us/locations-contact/kaiserslautern/]] | ||

| + | | | ||

| + | |[[File:Fraunhoder-IESE-Logo.png|left|120px|Fraunhofer IESE|link=https://www.iese.fraunhofer.de/en.html]] | ||

| + | |} | ||

|} | |} | ||

Latest revision as of 08:41, 18 February 2021

|

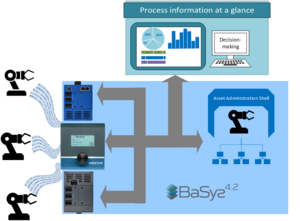

Retrofitting of Legacy Machines "BaSys structures our process data" - Marcel Kettering, Business Manager, WICO Textilbeschichtung und -kaschierung GmbH During production, machines in the shopfloor generate valuable process information which helps manufacturers in decision-making. A big challenge is to make this data accessible in one place, especially if data is connected from legacy machines without Industrie 4.0 interfaces. The Arendar IoT-Gateway collects "live" process information from shopfloor assets and makes it available for further processing. The Arendar connects shopfloor devices through analogue, digital and network I/O with the Eclipse BaSyx middleware and enables access to device data. Asset Administration Shells (AAS) and AAS sub models present data from different sources in a unified and structured manner and enable data access through defined APIs. The result is a digital production process that stores data from all relevant sources in a digital process model, which can be used in various ways. It provides holistic live process images to decision-makers who use them to identify and resolve problems faster. With the continuous process monitoring, manufacturers can detect machine failures earlier, control product quality during the production and perform real-time decision-making. Consequently, this improves the market responsiveness, reduces the maintenance costs and increases the production efficiency. | ||||||||||

|

|

|

Service-oriented production in a gear manufacturing line Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut aliquip ex ea commodo consequat. Duis autem vel eum iriure dolor in hendrerit in vulputate velit esse molestie consequat, vel illum dolore eu feugiat nulla facilisis at vero eros et accumsan et iusto odio dignissim qui blandit praesent luptatum zzril delenit augue duis dolore te feugait nulla facilisi. |

|

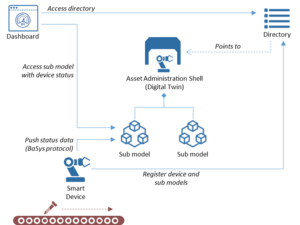

Integration of PLM Systems (BaSysPLM) "Eclipse BaSyx with its interoperable architecture enables us and our customers to bring product data directly from product development to manufacturing. This is relevant for highly variable Configure-to-Order products (-> lot size 1). Also feedback from the shop floor to the engineering (product type) as well as to single products (instances -> Digital Twins) can be realized." - Christian Muggeo, Team Lead Engineering Transformation, CONTACT Software GmbH

| ||||

|

|

|

BaSyx Edge Device Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut aliquip ex ea commodo consequat. Duis autem vel eum iriure dolor in hendrerit in vulputate velit esse molestie consequat, vel illum dolore eu feugiat nulla facilisis at vero eros et accumsan et iusto odio dignissim qui blandit praesent luptatum zzril delenit augue duis dolore te feugait nulla facilisi. |

|

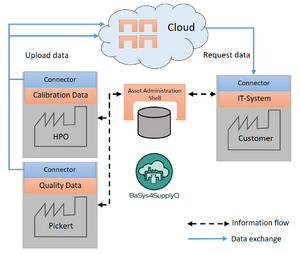

Information exchange with digital twins Many production processes are embedded into supply chains. Product related information is relevant throughout the whole product lifecycle and therefore needs to be exchanged between companies. Pickert & Partner GmbH and HPO Häfner Präzisionsteile Oberrot GmbH use Eclipse BaSyx to collect and provide product quality and calibration data that is exchanged with customers. This connection of product data and the IT that is enabled with Asset Administration Shells of Eclipse BaSyx realizes a horizontal integration that supports efficient data exchange and also enables new data-driven business models. | ||||||||

|

|

|

Experiment with BaSyx Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut aliquip ex ea commodo consequat. Duis autem vel eum iriure dolor in hendrerit in vulputate velit esse molestie consequat, vel illum dolore eu feugiat nulla facilisis at vero eros et accumsan et iusto odio dignissim qui blandit praesent luptatum zzril delenit augue duis dolore te feugait nulla facilisi. |

|

Digitalization of manufacturing process Digitalization of production processes yields considerable advantages for small scale enterprises (SMEs) in terms of optimized product and production planning. Eclipse BaSyx enables digital production processes that support the evaluation of orders with data from previous shipments. Eclipse BaSyx realizes Asset Administration Shells and Sub Models that provide process data to the ERP system, which implements the business logic for deciding about accepting or rejecting an order. This empowers SMEs to quickly, efficiently and reliably evaluate and plan the production as well as promptly meeting short term customer inquiries. Since the checking and creation of order processes can be automated, substantial improvement in flexibility and cost efficiency in the process of order acceptance in comparison to the legacy, and manual paper-based processes is realized. | ||||||||

|

|

|

Next generation shopfloor communication The integration of Eclipse BaSyx with messenger services enable a new communication style between workers and the shopfloor. This integration enables employees to flexibly access and exchange information by using BaSyx together with the Matrix Messenger. Chat bots give access to live machine data and services. They access production assets through Asset Administration Shells (AAS) to provide e.g. live data analysis or machine manuals on request. Also, threshold-breach alerts can be configured for relevant sensor values. Other possible applications are speech recognition as additional human machine interface, and indoor navigation. By using a hosted messenger, messages are routed thorugh a dedicated Matrix Messaging Server, instead of using public messenger services. |

||||||||||

|

|

Weitere Projekte:

- Digitalization of manufacturing process

- Parameter optimization for car supply manufacturing

- Integration with ERP systems

- Integration with BPMN engine for automating the manufacturing process

- Process anomaly monitoring

- Events / Exceptions

- Messenger bots

- Process dashboard

- Bild Dashboard

- Nutzen: Prozessanalyse & Entscheidungsunterstützung

- Nur 27% Unternehmen im Mittelstand nutzen Daten als Entscheidungsgrundlage