Notice: this Wiki will be going read only early in 2024 and edits will no longer be possible. Please see: https://gitlab.eclipse.org/eclipsefdn/helpdesk/-/wikis/Wiki-shutdown-plan for the plan.

ICE SFR Object Model

This page is under construction and can be considered... indecent. All numerical values listed are assumed to be under cold operating conditions.

Contents

Reactor Core Model

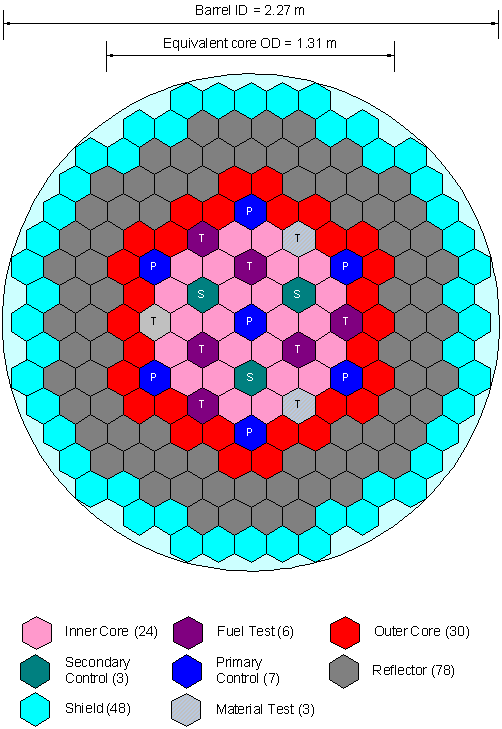

The SFR core is the highest level structure provided in the ICE object model hierarchy for sodium-cooled fast reactor modeling. The SFR reactor core is modeled as a radial arrangement hexagonal assemblies. Convention dictates assemblies are ordered with the center-most assembly being "row 1," the subsequent ring of assemblies surrounding it being "row 2," and so forth, iterating in concentric circles outwards.

The radial view of a SFR core is typically divided into five regions:

- inner core

- outer core

- radial blanket (optional)

- control assemblies

- radial reflectors

In addition to these, the entirety of the SFR core is contained within a shielding structure called the radial shield. The shield's purpose is to limit the amount of radiation that passes between the internal and external environments of the reactor core, although is not always depicted as part of a reactor core model. Additional assemblies may be included for fuel testing and materials testing.

In addition to fissile materials, an SFR can also contains fertile materials (such as U-238 or Pu-240) to be converted to fissile materials via neutron absorption (a process referred to as fuel breeding). The blanket regions of a reactor core are reserved exclusively for this purpose. A homogeneous core layout entails an even distribution of fertile material throughout the core fuel region by including an axial level of blanket within each assembly. This differs from a heterogeneous core layout which employs alternating concentric rows of pure fissile and fertile materials within the core region.

The presence of blanket materials inside a liquid-metal cooled reactor is the distinguishing factor between a breeder- and burner-type reactor. A breeder reactor contains fertile materials for fuel breeding, whereas a burner reactor does not, and simply burns through it's available fuel supply. At this time, the ICE SFR object model is assumed to handle burner-type reactors. However, the ability to include blanket assemblies is included for future modeling possibilities.

Objects of the reactor core include:

- Fuel Assemblies - Nuclear fuel components including inner core, outer core and—optionally—blanket assemblies. Inner and outer cores regions can contain both fissile and fertile materials, while the blanket region materials are exclusively fertile.

- Control Assemblies - Includes primary control rods, secondary (shutdown) control rods. Primary and secondary control rods are made of neutron-absorptive materials.

- Test Assemblies - Any fuels or materials included in the reactor core for the purpose testing during operations.

- Reflector Assemblies - A structure made of neutron-reflective material, causing subcritical fuels to become critical.

- Shield Assemblies - A stainless steel structure to shield the reactor core and external environments from irradiation.

Properties of the reactor core include:

- Type (SFR)

- Size - Total number of assemblies contained in the reactor core.

- Number and Location of Fuel Assemblies - Position of inner and outer core fuel assemblies at the core view, also called the core loading pattern.

- Number and Location of Control Assemblies - Position of control/shutdown rod assemblies at the core view.

- Number and Location of Testing Assemblies - Position of material and/or fuel testing assemblies at the core view.

- Number and Location of Reflector Assemblies - Position of radial reflector assemblies at the core view.

- Number and Location of Shield Assemblies - Position of shield assemblies at the core view.

- Inter-assembly Gap (cm) - Distance between the external walls of adjacent assemblies to allow for interstitial coolant flow.

- Lattice Pitch (cm) - Also called assembly pitch. The shortest distance between the centers of adjacent assemblies (also equivalent to the assembly outer flat-to-flat plus inter-assembly gap).

- Thermal Power (MWth) - Maximum heat the reactor is designed to generate.

- Electrical Power (MWe) - Maximum electricity the reactor is designed to generate.

- Thermal Efficiency - The ratio of thermal power to usable electrical power generated.

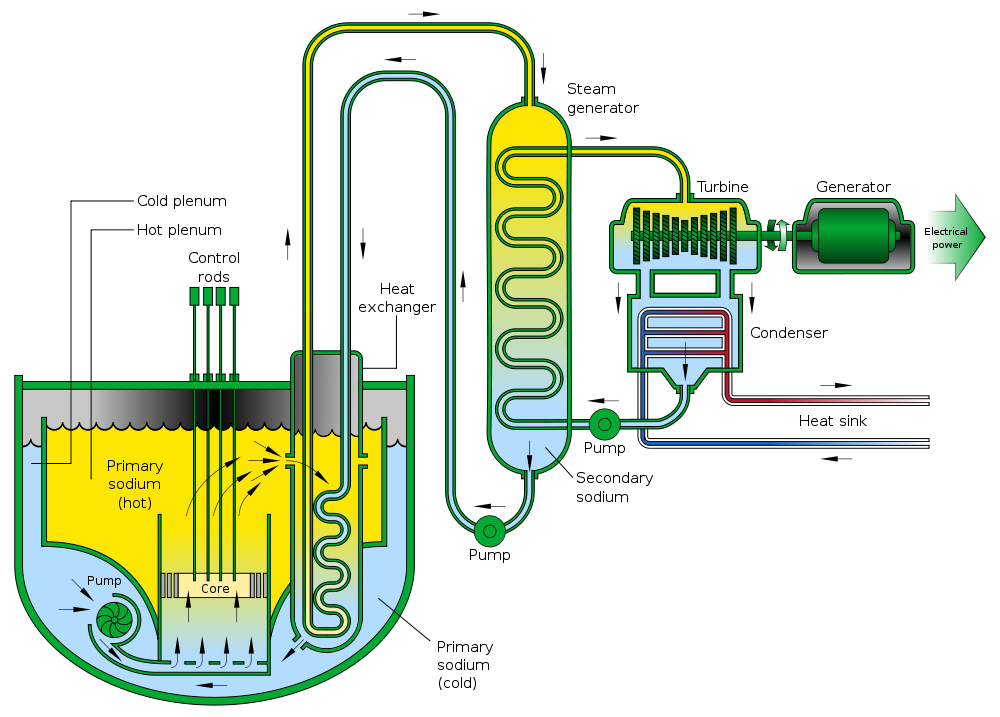

- Primary Coolant - Liquid sodium coolant.

- Inlet Temperature (°C) - Coolant temperature as it enters the bottom inlet of an assembly.

- Outlet Temperature (°C) - Coolant temperature as it exits the top outlet of an assembly.

- Reactor Temperature ΔT (°C) - Temperature difference between assembly inlets and outlets.

- Core Average Temperature (°C) - Average of inlet and outlet temperatures.

- Cycle Length - The length of time corresponding to one iteration of a fuel cycle.

Typical values are shown below:

Due to the migration of our wiki articles from MediaWiki to Markdown, the "locations" will not be displayed correctly. We will soon move back to MediaWiki, at which point this injustice will be righted.

- Type = SFR

- Size = 199

- Locations of Fuel Assemblies (1/3rd symmetry of reactor core):

O - I I -

O I - I I

O - I I - I

O O - I I -

O O - O O

O O - -

- - - - -

I = Inner core assembly (24 total); O = Outer core assembly (30 total)

- Locations of Control Assemblies (1/3rd symmetry):

P

P - - S -

P - -

- - - - -

P = Primary control assembly (7 total); S = Secondary control assembly (3 total)

- Location of Test Assemblies (1/3rd symmetry):

M - - -

F - -

F - - M

- - - - -

F = Fuel test assembly (6 total); M = Material test assembly (3 total)

- Locations of Reflector Assemblies (1/3rd symmetry):

R R - - - - -

R R - - - - -

R R - - - - - -

R R - - - - - -

R R R - - - - -

R R R R - - R R

R R R R R R R

R R R R - -

R = Radial reflector assembly (78 total)

- Locations of Shield Assemblies (1/3rd symmetry):

S - - - - - - - S - - - - - - - S - - - - - - - - S - - - - - - - - S - - - - - - - - S - - - - - - - - S S - - - - - - - S S - - - - S S S S S S S

S = Shield assembly (48 total)

- Inter-assembly Gap = 0.4000 cm

- Lattice Pitch = 14.5980 cm

- Thermal Power = 250 MWth

- Electrical Power = 95 MWe

- Thermal Efficiency = 38%

- Primary Coolant = Na

- Inlet Temperature = 355°C

- Outlet Temperature = 510°C

- Reactor Temperature ΔT = 155°C

- Core Average Temperature = 432.5°C

- Cycle Length = 4 months

Reactor Assembly Model

A SFR core can contain anywhere from a few dozen to several hundred assemblies (sometimes referred to as sub-assemblies), all of which can be categorized into one of five different types:

A SFR core can contain anywhere from a few dozen to several hundred assemblies (sometimes referred to as sub-assemblies), all of which can be categorized into one of five different types:

- fuel

- control

- test

- reflector

- shield

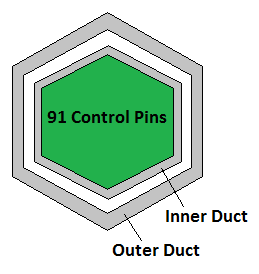

In the ICE SFR object model, these assemblies can be categorized into two types: pin-containing assemblies, and rod-containing assemblies. Pin-containing assemblies constitute the majority of assemblies in a SFR core, and include fuel, control, test and shield assemblies. Reflector assemblies differ in that they contain solid rods of steel (rather than pins), and are thus labelled as a rod-containing assembly.

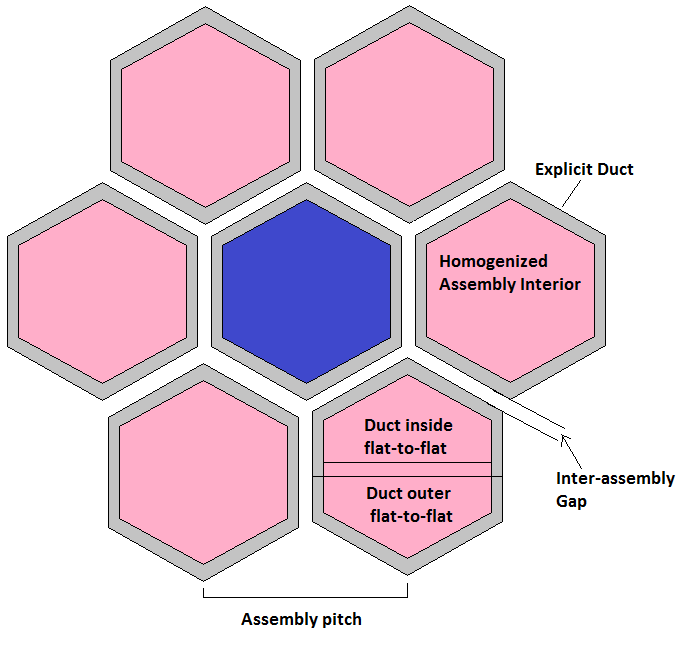

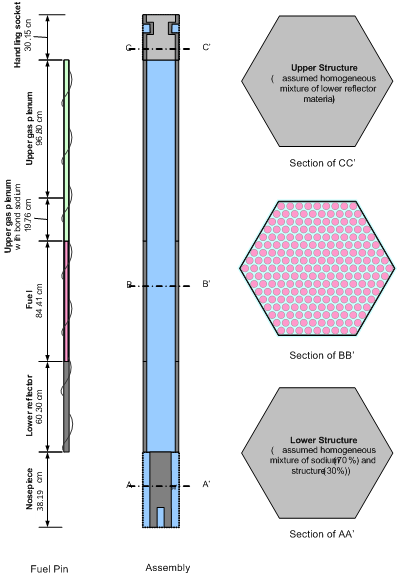

The SFR assembly consists of an external hexagonal stainless steel duct containing an array of cylindrical pins or rods arranged in a triangular lattice, known as a pin/rod bundle. Pins and rods are indexed within the assembly in a manner similar to assemblies at the core level: the center-most pin/rod is labeled "row 1," the concentric circle around it being "row 2," and so forth. Each pin/rod has a stainless steel helical wire wrap around the exterior. This wire wrap provides uniform spacing of the pins/rods within the assembly through which sodium coolant can flow, in place of a grid spacer like one would typically find in an LWR.

Basic objects of all SFR assemblies are:

- Duct - A hexagonal stainless steel tube housing the pins or rods in a triangular lattice.

- Nosepiece - Slotted ports at the bottom of the assembly, allowing coolant to flow upwards and through the assembly structure.

- Handling Socket - A structural end-cap located at the top of an assembly, allowing the assembly to be handled from above.

Properties of all SFR assemblies include:

- Size - Number of pins or rods contained inside a SFR assembly. Each assembly contains <math>\scriptstyle 3\times(r^{2}~-~r)~+~1</math> pins/rods, indexed in concentric circles starting with the center-most pin/rod being "row 1."

- Assembly Type - Either fuel, control, test, reflector or shield assembly.

- Duct Material

- Nosepiece Material

- Handling Socket Material

- Duct Outer Flat-to-Flat Distance (cm) - The distance between parallel exterior duct walls of an assembly.

- Duct Wall Thickness (cm) - Thickness of the hexagonal steel duct enclosing each fuel assembly.

- Duct Inner Flat-to-Flat Distance (cm) - The distance between parallel interior duct walls of an assembly.

- Handling Socket Height (cm)

- Nosepiece Height (cm)

- Total Fuel Assembly Height (cm)

The default SFR assembly can have the following values:

- Duct Material = HT-9 steel

- Nosepiece Material = SS-316 steel

- Handling Socket Material = SS-316 steel

- Duct Outer Flat-to-Flat Distance = 14.1980 cm

- Duct Wall Thickness = 0.3000 cm

- Duct Inner Flat-to-Flat Distance = 13.5980 cm

- Handling Socket Height = 30.00 cm

- Nosepiece Height = 38.00 cm

- Total Fuel Assembly Height = 328.000 cm

It is assumed that all assemblies in the ICE SFR object model inherit the above parameters and values. Typical values not listed above are implemented on a per-assembly-type basis, as outlined in the following sections.

Fuel Assembly

The fuel assembly is a pin-containing assembly, and contains fissile materials, namely oxide (PuO2, UO2) or mixed-oxide (PuO2-UO2) fuels. Different types of fuel assemblies can be distinguished from one another by their inclusion in either the inner and outer core regions. This distinction usually corresponds to differences in fuel material concentrations (for example, 14.6 wt% Pu and 17.0 wt% Pu in the inner and outer cores, respectively), but can also include factors such as differences in coolant flow rates or power densities.

Additional objects of the fuel assembly include:

- Fuel Pins - Also known as the fuel pin bundle, can include inner core, outer core and blanket pins.

Properties of a fuel assembly include:

- Pin Type - Either inner core, outer core or (optionally) blanket assembly.

- Pin Pitch (cm) - Distance from a reactor pin center to an adjacent pin's center.

- Duct-Bundle Clearance (cm) - The gap separating the pin bundle lattice from the duct, along each wall of the assembly.

- Outer Duct Perimeter (cm) - Total perimeter of the assembly duct's exterior wall.

- Inner Duct Perimeter (cm) - Total perimeter of the assembly duct's interior wall.

- Lattice Perimeter (cm) - (?)

- Lattice Area (cm2) - (?)

- Flow Area (cm2) - (?)

- Wetted Perimeter (cm) - The total perimeter in a cross-sectional view of the assembly that is in contact with the liquid coolant. Equal to

<math>P~=~\sum\limits_{i=1}^\infty~l_{i}</math>,

where <math>l_{i}</math> is the perimeter of each surface in contact with coolant.

- Hydraulic Diameter (cm) - A term useful in calculating coolant flow in non-cylindrical structures. Equal to

<math>D_{H}~=~\frac{4A}{P}</math>,

where <math>A</math> is the total flow area, and <math>P</math> is the wetted perimeter.

- Pin Bundle Height (cm)

Reasonable values for a fuel assembly are as follows:

- Size = 217 (9 rows)

- Pin Pitch = 0.9080 cm

- Pin Bundle Height = 260.00 cm