Notice: this Wiki will be going read only early in 2024 and edits will no longer be possible. Please see: https://gitlab.eclipse.org/eclipsefdn/helpdesk/-/wikis/Wiki-shutdown-plan for the plan.

Difference between revisions of "BaSyx"

m (Fixed minor typo.) |

m (→Industrie 4.0) |

||

| Line 17: | Line 17: | ||

== Industrie 4.0 == | == Industrie 4.0 == | ||

| − | Industrie 4.0 is the fourth industrial revolution. | + | [https://en.wikipedia.org/wiki/Industry_4.0 Industrie 4.0] is the fourth industrial revolution. Industrial revolutions were triggered by the availability of new technology and had significant impact on productivity, but also on production processes. With every industrial revolution, the availability of products did change, and so did the lifestyle of people. |

[[File:basyx.Industrie40.png|thumb|Four industrial revolutions - by Christoph Roser at AllAboutLean.com]] | [[File:basyx.Industrie40.png|thumb|Four industrial revolutions - by Christoph Roser at AllAboutLean.com]] | ||

| − | * The first industrial revolution did happen at the end of the 18th century. The introduction of water and steam powered machines did trigger this industrial revolution. The availability of machines did support human workers and enabled a more efficient production | + | * The first industrial revolution did happen at the end of the 18th century. The introduction of water and steam powered machines did trigger this industrial revolution. The availability of machines did support human workers and enabled a more efficient production. |

* The second industrial revolution was based on the principle of the division of labor. Electricity and the conveyor belt enabled mass-production that was the foundation for the availability of cheap, mass-produced goods. Many workers that did work on the conveyor belt had to perform repetitive tasks for each product with a defined frequency to ensure constant production. | * The second industrial revolution was based on the principle of the division of labor. Electricity and the conveyor belt enabled mass-production that was the foundation for the availability of cheap, mass-produced goods. Many workers that did work on the conveyor belt had to perform repetitive tasks for each product with a defined frequency to ensure constant production. | ||

| Line 30: | Line 30: | ||

| − | The first three industrial revolutions did | + | The first three industrial revolutions did improve the efficiency of production processes, and therfore enabled cheaper production of mass-produced products. Improving of cheap mass production is also one aspect of the fourth industrial revolution. The full digitalization of production processes reduces unwanted down-times, reduces production cost, and enables more predictable production processes. |

| + | |||

| + | Another major aspect of Industrie 4.0 is the enabling of new business models and the ability to provide more changeable production processes. The ability to react more quickly to market demands is a major future unique selling point for manufacturing companies. Digitalized production processes enables the efficient production of small lot sizes, the mass customization. Our vison of Industrie 4.0 is to provide the ability to produce individualized and tailored products with the same efficiency as large numbers of mass produced items. The connection of devices and IT-systems enables big data analytics that support early detection of defects and prediction of production failures. This increases productivity and presents unplanned downtimes of production lines. Big data processing requires the analysis of massive amounts of data. It makes sense to collect this data from multiple data sources, e.g. multiple companies. Industrie 4.0 enables the business of specific analysis companies that analyze data from 3rd parties to optimize production for their customers. | ||

The BaSys 4.0 middleware provides supports Industrie 4.0 application scenarios with open source components and open interfaces that enable connectivity of production entities. | The BaSys 4.0 middleware provides supports Industrie 4.0 application scenarios with open source components and open interfaces that enable connectivity of production entities. | ||

Revision as of 04:12, 12 June 2019

Eclipse BaSyx & BaSys 4.0

Eclipse BaSyx is the open source platform for next generation automation. Our mission is to provide a free software platform that enables all interested parties, large and small industries, research institutes, academia, and interested persons, to participate and to shape the fourth industrial revolution. We believe that the availability of a free reference technology platform is a key success factor for the Industrie 4.0. Eclipse BaSyx therefore provides common and re-useable Industrie 4.0 components and an SDK that supports the development of new Industrie 4.0 software components to enable the rapid development of Industrie 4.0 solutions. This Eclipse BaSyx platform furthermore will provide reference application scenarios for common Industrie 4.0 challenges. Eclipse BaSyx is actively supported by the BaSys 4.0 (Homepage, in German) research project, which is funded by the German Ministry for Education and Research (BMBF, grant no. 01IS16022). BaSys 4.0 researches and specifies key concepts of Industrie 4.0, participates in standardization activities, and integrates existing standards and technologies into an Industrie 4.0 middleware.

BaSyx Project Documentation

- BaSyx benefits and use-cases

- BaSyx feature overview

- BaSyx explained in 10 minutes

- BaSyx application scenarios

- BaSyx documentation

- BaSyx status

- Downloading BaSyx

- Examples

- Publications

- Glossary and abbreviations

Industrie 4.0

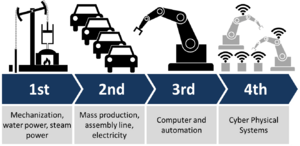

Industrie 4.0 is the fourth industrial revolution. Industrial revolutions were triggered by the availability of new technology and had significant impact on productivity, but also on production processes. With every industrial revolution, the availability of products did change, and so did the lifestyle of people.

- The first industrial revolution did happen at the end of the 18th century. The introduction of water and steam powered machines did trigger this industrial revolution. The availability of machines did support human workers and enabled a more efficient production.

- The second industrial revolution was based on the principle of the division of labor. Electricity and the conveyor belt enabled mass-production that was the foundation for the availability of cheap, mass-produced goods. Many workers that did work on the conveyor belt had to perform repetitive tasks for each product with a defined frequency to ensure constant production.

- The third industrial revolution is based on electronics and IT. More and more simple, repetitive production steps were automated with e.g. robots. Programmable Logic Controllers (PLC) enabled the automation of factories. Machines did take over more and more production tasks, and were increasingly substituting human workers in factories.

- The fourth industrial revolution is based on the end-to-end digitalization and end-to-end networking of production. By connecting formerly unconnected entities of production facilities, production is not only becoming more efficient, but also new business models become possible.

The first three industrial revolutions did improve the efficiency of production processes, and therfore enabled cheaper production of mass-produced products. Improving of cheap mass production is also one aspect of the fourth industrial revolution. The full digitalization of production processes reduces unwanted down-times, reduces production cost, and enables more predictable production processes.

Another major aspect of Industrie 4.0 is the enabling of new business models and the ability to provide more changeable production processes. The ability to react more quickly to market demands is a major future unique selling point for manufacturing companies. Digitalized production processes enables the efficient production of small lot sizes, the mass customization. Our vison of Industrie 4.0 is to provide the ability to produce individualized and tailored products with the same efficiency as large numbers of mass produced items. The connection of devices and IT-systems enables big data analytics that support early detection of defects and prediction of production failures. This increases productivity and presents unplanned downtimes of production lines. Big data processing requires the analysis of massive amounts of data. It makes sense to collect this data from multiple data sources, e.g. multiple companies. Industrie 4.0 enables the business of specific analysis companies that analyze data from 3rd parties to optimize production for their customers.

The BaSys 4.0 middleware provides supports Industrie 4.0 application scenarios with open source components and open interfaces that enable connectivity of production entities.